Dimitriou Fabrications operate from modern purpose built facilities. With experience across all areas of manufacturing, Dimitriou Fabrications have the ability to offer clients industry best manufacturing techniques.

Dimitriou Fabrications hold the enviable reputation as leaders in the manufacture of new machinery for industry leading OEM’s. With the ability to perform all areas of fabrication under one roof, Dimitriou Fabrications are well placed to offer lower manufacturing costs, whilst benefiting from reduced lead times.

The value Dimitriou Fabrications deliver to the industry is demonstrated by the volume of repeat business they receive from their clients.

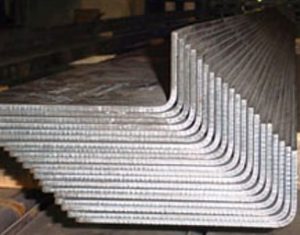

BRAKE PRESSING

Dimitriou Fabrications boast one of the largest capacity brake presses in NSW. Our presses range in capacity from 300 to 2,000 tonne. With experience in pressing both mild steel to Quench and Tempered material, we have serviced clients all over Australia. Our ability to develop, process and form material in-house establishes our reputation as the supplier of choice.

BRAND S & E

CAPACITY 2,000 Tonne

LENGTH 3,200 mm between columns

Digital Numerical Control

BRAND Pearson

CAPACITY 350 Tonne

LENGTH 3,000 mm open columns

Digital Numerical Control

BRAND Pearson

CAPACITY 300 Tonne

LENGTH 5,000 mm open columns

Digital Numerical Control

PLATE ROLLING

Dimitriou Fabrications can also perform your rolling duties on site. Our Roundo plate rolling machine effortlessly forms conical sections and cylinders up to 3,000mm in length. With our in-house development programming, Dimitriou Fabrications are able to form complex developments, which can be downloaded directly into our High Definition Plasma for quick and accurate material processing.

Rolling Capabilities

Cone bending attachment

Hardened and ground rolls

Digital displays showing the position of lower rolls

GUILLOTINING

Advantages of guillotining include quick and efficient shearing of material eliminating any concerns of distortion typically experienced by heat introduced through oxy cutting. However with the use of our new High Definition Plasma, such concerns have since been eliminated.

Guillotining Capabilities

3,048mm x 10mm thick plate

Digital Numerical Control

Geka Punch / Cropper

CNC Bandsaw

HEAVY PIPE DEVELOPMENTS

With our broad range of in-house facilities and expertise, Dimitriou Fabrications are well equipped to perform all forms of heavy pipe fabrications both quickly and economically.

Our team of CAD programmers have the latest technology to perform all your requirements using industry best practices.

Utilizing the modern services of Advanced Profile Cutting, material can be processed to within +/- 1mm tolerances before forwarding onto our rolling and pressing facilities. Thereafter items can be welded to your specific requirements and any NDT can be performed on-site to further reduce lead times and costs.

HEAVY PLATE FABRICATIONS

With 40 years experience in the manufacture of various large capacity mining machines, Dimitriou Fabrications pride ourselves on our ability to perform all your heavy plate work requirements without the need to sub-contract services off-site.

Dimitriou Fabrications are able to process your material directly from the mill, form as required utilizing either in-house rolling, or pressing facilities, before our dedicated boilermakers and qualified welders take over. Final stages typically involve the services of our Machine shop facilities.

Dimitriou Fabrications aim to provide a complete value added service to clients from start to finish. Taking complete control over costs, delivery and quality ensures our clients benefit from our in-house efficiencies and experience whilst operating to ISO9001:2008.

LARGE IN-HOUSE TRIAL ASSEMBLIES

Dimitriou Fabrications operate from dedicated facilities, specifically designed to ensure large projects can be trial assembled on site, and more importantly under cover. As such our facilities include multiple over head cranes to assist in handling larger jobs safely. The fabrication shop alone exceeds 2,000 sqm with 9m clearance under crane hook. When combined with our other facilities, our total under cover workshop area totals 7,000sqm.

Third party client inspections can be performed in-house to ensure any concerns or modifications can be addressed prior to delivery to site.

LARGE SHUTDOWN REFURBISHMENTS

Dimitriou Fabrications ability to perform all facets of manufacturing from material profiling, to forming, fabrication, and final machining has proven to be beneficial to those clients requiring projects to be completed within tight lead times. Not having to rely on external parties for any process in the manufacturing cycle, allows Dimitriou Fabrications to take control and responsibility of your project from start to finish.

The ability of Advanced Profile Cutting to stock all local Bluescope plate in both 250 grade and 350 grade, with selected ranges of Bissalloy 80 and 400 grades, ensures Dimitriou Fabrications can take immediate action upon unexpected breakdowns in your industry.